Printed Circuit Boards (PCBs) find use in a wide variety of electronic equipment and products. These circuit boards allow everything from desktop computers to irrigation systems to function. In medical and aerospace applications, PCBs and the systems that rely on them may be essential to human safety, as well.

Unfortunately, circuit boards can become damaged during and after the manufacturing process. In most cases, businesses discard damaged PCBs and replace, a costly method of dealing with the sometimes unavoidable accidents that occur during manufacturing.

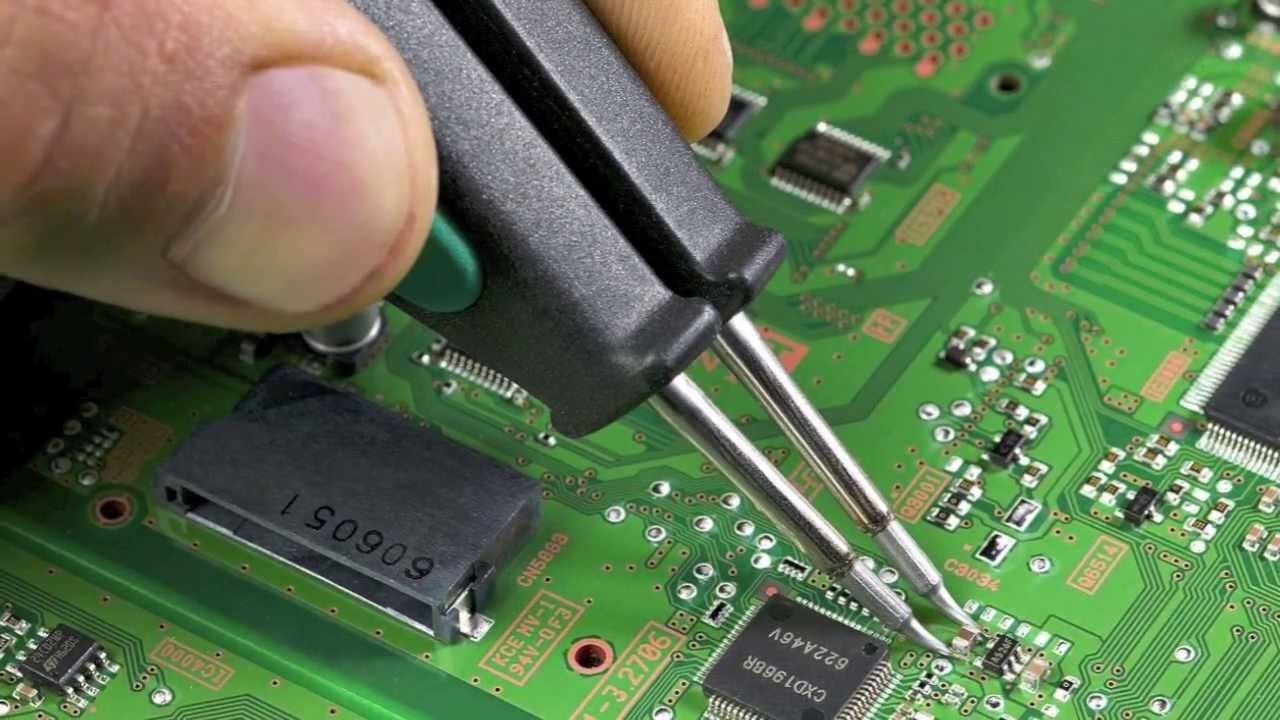

Alternatively, some PCB and electronics manufacturers look to printed circuit board repair for damaged and defective circuit boards, transforming flawed PCBs into functioning products. By investing in this strategy, you can decrease your operation’s waste and increase product yields.

To assist PCB manufacturers, product development companies and other businesses reliant on circuit boards, Precision PCB Services provides repair and rework, high-tech rework stations, employee training and consulting to help manufacturers identify process flaws. Learn more about the different PCB repair and rework services we offer for printed circuit boards.

Purpose of Printed Circuit Board Repair

A PCB can become damaged during and after manufacture. A circuit board may need repair or rework for a number of reasons, such as the following:

- There was a flaw in the manufacturing process

- A design flaw was detected after manufacturing

- The printed circuit board was mishandled or suffered impact damage

- The PCB has excess solder, broken traces or other problems

Repairing these faults instead of discarding the entire circuit board can help you identify problems with your manufacturing process and save a project gone wrong without breaking the bank.

At Precision PCB Services, we offer a number of PCB repair and rework services to help clients recover damaged circuit boards and improve their manufacturing and in-house repair processes.

The following common PCB repairs done with SAK

Gold Finger Contact Repair: Gold finger contacts on the edge of a PCB are vulnerable to solder splash and contamination. We can help your team repair or replace damaged contacts and prevent the problem from recurring.

Laminate Repair: Imperfections in PCB laminate also warrant repair. The type of process adjustment will depend on the nature of the damage.

Trace Repair: Copper traces connect elements on your PCB, making them some of the most essential components. Trace repair can make many defective PCBs functional.

Circuit Modification: This process can help manufacturers fix design flaws after manufacturing.

Inner Layer Repairs: Precision PCB Services can also assist you with inner layer repairs for multilayer circuit boards.